Supercritical CO₂ extraction is transforming perfume production by offering a cleaner, efficient method for obtaining fragrance compounds without harmful chemicals. Unlike older techniques like steam distillation or hexane extraction, this process uses pressurized CO₂ to extract high-quality aromatic oils while preserving delicate scent molecules. Key benefits include:

- Purity: Leaves no chemical residues, ensuring safer, cleaner extracts.

- Efficiency: Produces higher oil yields (e.g., 12.41% for patchouli vs. 2.8% via steam distillation).

- Eco — Friendliness: CO₂ is reusable, reducing waste and reliance on petrochemical solvents.

- Low Heat Impact: Operates at ~31.1°C (88°F), avoiding damage to heat-sensitive compounds.

This method is gaining traction for its ability to preserve authentic scent profiles, process rare botanicals, and align with green practices. As equipment becomes more accessible, the perfume industry is poised to adopt this technique widely, reshaping fragrance creation.

What is Supercritical CO2 Extraction?

Supercritical CO₂ extraction transforms carbon dioxide into a powerful solvent by subjecting it to conditions above its critical point - 31.1°C (≈88°F) and 7.38 MPa (≈73 atmospheres). At this state, CO₂ takes on a dual nature, combining the density of a liquid with the diffusivity of a gas. This unique combination makes it exceptionally effective in perfume production. Its gas-like properties allow it to penetrate deep into plant materials, reaching even the smallest cellular structures, while its liquid-like density efficiently dissolves and carries aromatic compounds. This balance is what makes supercritical CO₂ extraction so successful in capturing delicate fragrances.

When the pressure is released, the CO₂ reverts to its gaseous form, leaving behind a pure, solvent-free extract. This process not only ensures thorough extraction but also preserves the integrity of the fragrance, a critical requirement for crafting high-quality perfumes.

Why CO2 Works for Clean Extraction

CO₂ stands out as an ideal solvent for preserving the essence of fragrances, thanks to its unique properties and eco-friendly profile. It is non-toxic, non-flammable, and chemically inert, meaning it doesn’t alter the delicate molecular structure of the fragrance compounds it extracts. Recognized by the U.S. FDA as "Generally Recognized as Safe" (GRAS), CO₂ is widely accepted for use in cosmetics and food-grade applications. These qualities have made it the solvent of choice for more than 90% of all supercritical fluid extractions worldwide.

Another advantage of CO₂ is its reusability. Industrial systems are designed to capture and recycle the CO₂ after each extraction cycle, making the process far less wasteful than traditional methods that rely on petrochemical solvents, which often require disposal. This closed-loop system not only minimizes waste but also supports the industry’s shift toward sustainability and environmentally responsible practices. As Fanlin Zhou from Guangzhou Xinhua University explains:

"SC — CO₂ extraction aligns with green chemistry principles while meeting industrial requirements for safety, sustainability, and high sensory quality".

How Supercritical CO₂ Extraction Works in Perfumery

The Extraction Process

Supercritical CO₂ extraction is a multi-step process involving compression, extraction, separation, and recycling. It begins by heating and pressurizing carbon dioxide beyond its critical point - 31.1°C and 7.38 MPa - where it becomes a supercritical fluid. In this state, CO₂ exhibits the unique properties of both a gas and a liquid: it can penetrate plant cells like a gas while dissolving essential oils and terpenes like a liquid. The supercritical CO₂ is pumped into an extraction vessel containing botanical material, where it works to extract aromatic compounds. Once the extraction is complete, the pressure is reduced in a separator, causing the aromatic extract to precipitate. The CO₂ is then recycled for reuse, making the process efficient and resource-conscious.

In September 2022, researchers Syaifullah Muhammad and Abdul Khalil from Universitas Syiah Kuala and Universiti Sains Malaysia showcased the efficiency of this method by extracting patchouli at 20 MPa and 80°C (176°F). Their efforts yielded an impressive 12.41% crude oil - far exceeding the 1–3% typically obtained through steam distillation. Additionally, they preserved patchouli alcohol concentrations of up to 53.66%, compared to just 22.70% found in steam-distilled extracts.

This advanced approach not only enhances yield but also protects the delicate balance of aromatic compounds, ensuring the preservation of authentic scent profiles.

Preserving Natural Scent Profiles

One of the standout features of supercritical CO₂ extraction is its ability to maintain the true aroma of botanicals. Operating at relatively low temperatures - usually between 31°C and 40°C (88°F to 104°F) - the process avoids the thermal degradation that often occurs during steam distillation, which requires temperatures exceeding 100°C (212°F). This gentle handling safeguards heat-sensitive compounds, such as monoterpenes, which are vital for the top notes in fragrances.

This precision is especially important for rare and delicate botanicals. For example, myrrh contains furanodienes, which are highly unstable at high temperatures. Traditional steam distillation can destroy these compounds, but supercritical CO₂ extraction preserves them, maintaining a standardized 4% furanodiene level and ensuring both potency and aromatic integrity.

The method also allows for adjustable selectivity. By tweaking pressure and temperature, extractors can isolate specific fragrance molecules while excluding undesirable components like waxes or heavy lipids. In April 2024, researchers at Charles University, led by Veronika Pilařová, developed a two-step process that demonstrated this precision. They used CO₂ with a minimal 2% ethanol cosolvent for 20 minutes to isolate non-polar volatile terpenes, followed by a second step to extract polar compounds. This approach was successfully tested on seven different plant species, highlighting its versatility and effectiveness.

Advantages of Supercritical CO₂ Over Conventional Methods

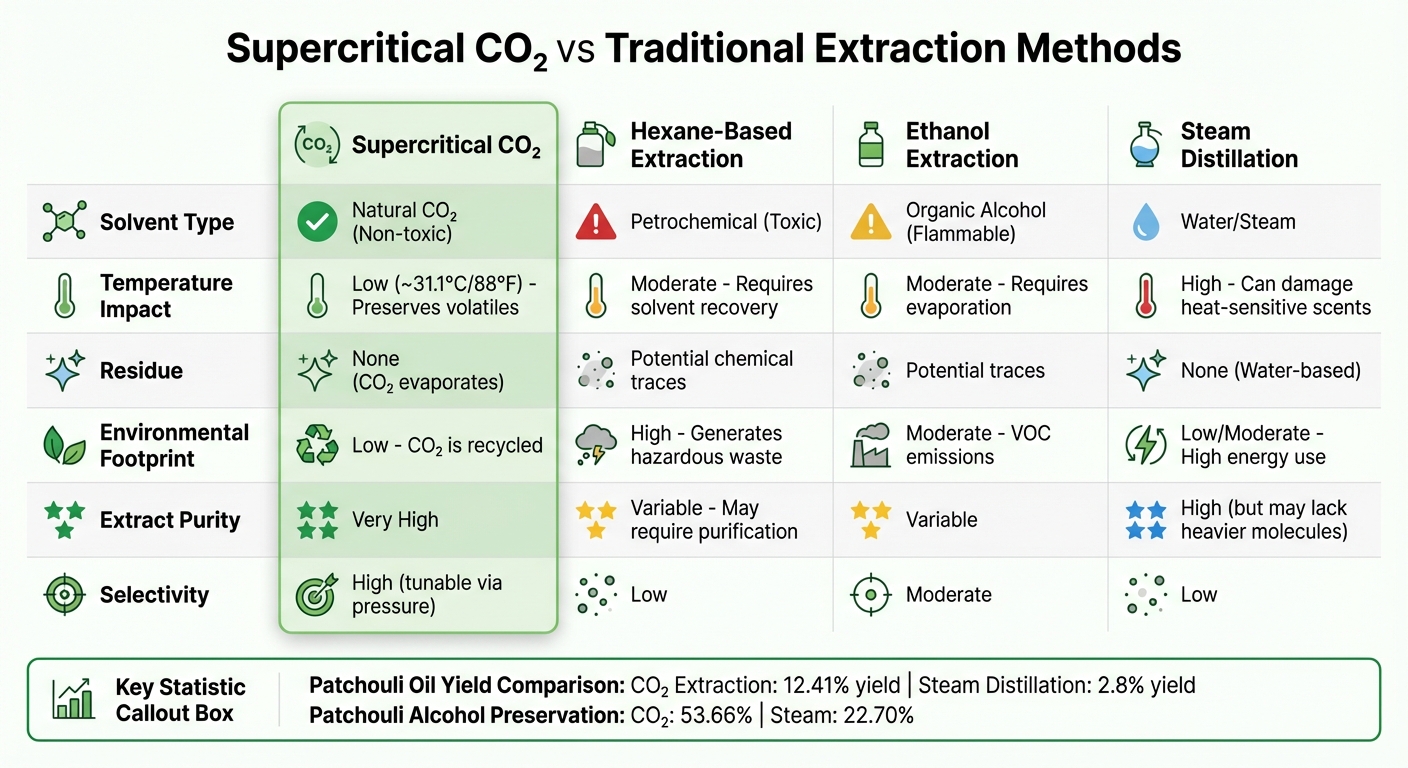

CO2 vs Traditional Perfume Extraction Methods Comparison

Lower Environmental Impact

Supercritical CO₂ extraction stands out for its eco-friendly approach by completely avoiding hazardous petrochemical solvents like hexane, ethanol, or acetone, which are known to harm both human health and the environment. This method operates within a closed-loop system, allowing CO₂ to be continuously recovered and reused. Interestingly, the CO₂ used is often sourced as a byproduct from other industrial activities, making it a more sustainable choice. Unlike solvent-based methods that produce hazardous waste, this process generates no toxic byproducts or effluents.

Another key advantage is its lower energy consumption. With CO₂’s critical point set at approximately 31.1°C (88°F), the process requires significantly less energy compared to high-temperature techniques like steam distillation. This energy efficiency not only reduces waste but also ensures a cleaner and purer final extract.

Higher Purity and Scent Quality

One of the standout features of supercritical CO₂ extraction is its ability to leave behind a completely pure extract, free from any residual chemicals. Compare this to hexane-based methods, which must ensure residual solvent levels stay below 1 part per million to avoid contamination.

The process also creates a gentle, oxygen-free environment, which is crucial for preserving the natural aroma of botanicals. This not only enhances the richness and authenticity of the scent but also extends the shelf life of the extract. For example, in a study on patchouli, supercritical CO₂ extraction retained an impressive 38.70% concentration of patchouli alcohol, compared to just 22.70% in steam-distilled extracts. This demonstrates its ability to produce a fuller and more vibrant scent profile.

Comparison Table: CO₂ vs Conventional Methods

Here’s a breakdown of how supercritical CO₂ extraction measures up against other conventional methods:

| Factor | Supercritical CO₂ | Hexane — Based Extraction | Ethanol Extraction | Steam Distillation |

|---|---|---|---|---|

| Solvent Type | Natural CO₂ (Non-toxic) | Petrochemical (Toxic) | Organic Alcohol (Flammable) | Water/Steam |

| Temperature Impact | Low (approx. 31.1°C/88°F); preserves volatiles | Moderate; requires solvent recovery | Moderate; requires evaporation | High; can damage heat-sensitive scents |

| Residue | None (CO₂ evaporates) | Potential chemical traces | Potential traces | None (Water-based) |

| Environmental Footprint | Low; CO₂ is recycled | High; generates hazardous waste | Moderate; VOC emissions | Low/Moderate; high energy use |

| Extract Purity | Very High | Variable; may require further purification | Variable | High (but may lack heavier molecules) |

| Selectivity | High (tunable via pressure) | Low | Moderate | Low |

This table underscores the superior performance of supercritical CO₂ extraction across multiple factors, from environmental considerations to extract quality and purity.

Your Personal Fragrance Expert Awaits

Join an exclusive community of fragrance connoisseurs. Each month, receive expertly curated selections from over 900+ brands, delivered in elegant 8ml crystal vials. Your personal fragrance journey, meticulously crafted.

Try Your First MonthResearch and Industry Applications in Perfumery

Recent Studies on CO₂ Extraction

Scientific advancements continue to highlight the benefits of supercritical CO₂ extraction in preserving the true essence of natural scents. For instance, a study published in September 2022 by researchers from Universitas Syiah Kuala and Universiti Sains Malaysia demonstrated that CO₂ extraction delivers a higher yield and purity of patchouli oil compared to steam distillation. Notably, it excels at preserving patchouli alcohol, the compound that gives patchouli its prized, earthy aroma.

In another major development, researchers at Charles University introduced a two-step supercritical fluid extraction (SFE) method in April 2024. This approach first isolates volatile terpenes from plants and then extracts polar compounds like flavonoids. By targeting aromatic molecules with precision, this method showcases the efficiency and versatility of CO₂ extraction, paving the way for practical industry applications.

Industry Examples and Applications

These scientific breakthroughs are finding real-world applications as industry leaders embrace supercritical CO₂ extraction. One notable example is SFE Process, a French technology firm that has developed a portable CO₂ extractor called "SIY" (Scent It Yourself). This mobile unit allows perfume sourcers to capture the essence of fresh plants directly in the field, preventing the degradation that often occurs during transport. According to the company, this method retains the olfactory qualities of raw materials "as close as possible to those of natural sources".

This technology proves especially effective with delicate botanicals like jasmine, lilac, elderflower, and marigold - flowers that are notoriously difficult to process using traditional steam distillation. Supercritical CO₂ extraction preserves their authentic scent profiles without exposing them to damaging heat.

Beyond capturing essential oils, manufacturers are also leveraging CO₂ extraction for fixative agents such as myrrh. These extracts, standardized to 4% furanodienes, help reduce evaporation rates and enhance perfume stability. This shift not only improves product quality but also aligns with the industry’s move toward more sustainable practices by minimizing reliance on petrochemical solvents. With over 150 industrial-scale SFE plants now operational worldwide, supercritical CO₂ extraction is no longer experimental - it’s becoming a standard in modern perfumery production.

Future Developments and Industry Impact

Making CO₂ Technology More Accessible

Supercritical CO₂ extraction has traditionally been reserved for large-scale operations due to its high equipment costs. However, this is starting to change. Manufacturers are now designing more efficient systems, such as the SIY portable extractor from SFE Process. This innovative device allows perfume creators to collect fresh botanical essences directly on-site, eliminating the need for permanent factory setups.

Advances in mathematical modeling are also helping to streamline the process. By predicting optimal yields, these models reduce the need for costly pilot tests. For example, in October 2025, researchers used Response Surface Methodology to fine-tune extraction conditions - 25 MPa, 50 °C, and an 8 L/h flow rate - achieving a 1.12% yield of Phoenix Dancong tea oil while cutting energy consumption. These breakthroughs make the technology more accessible and energy-efficient, paving the way for broader environmental applications, which will be discussed further in the next section.

Reducing Petrochemical Solvent Use

A major benefit of supercritical CO₂ extraction is its ability to reduce reliance on petrochemical solvents like hexane. Unlike traditional solvents, which often require additional separation steps and can leave residues, CO₂ naturally reverts to a gas after extraction. This eliminates chemical waste and lowers energy requirements.

The rise of "Green Analytical Chemistry" is further driving adoption. New protocols now optimize co-solvent levels, enabling the capture of a wider range of compounds in a single run. This eliminates the need for multiple extraction stages, saving both time and resources. Such advancements are particularly impactful for processing rare and delicate botanicals, which require careful handling.

Extracting Rare and Delicate Botanicals

Supercritical CO₂ extraction is opening new doors for processing botanicals that are sensitive to heat. Operating at temperatures between 35–55 °C (95–131 °F), this method avoids the thermal degradation seen with traditional steam distillation, which often reaches 100 °C (212 °F) or higher. Flowers like jasmine, lilac, elderflower, and tuberose, which are prone to losing their unique scent profiles under high heat, can now be preserved more effectively. As Kershen Teo of Prosody London explains:

"The difference for CO₂ extracted is always nearly more three dimensional and near 100% true to the real flower".

This precision is especially valuable for rare resins and botanicals with fragile compounds. For instance, manufacturers can now produce standardized extracts of myrrh with bioactive profiles - such as 4% furanodienes - that would otherwise degrade under conventional heat-based methods. By preserving these delicate molecules, perfumers gain access to a broader and more authentic range of natural materials, allowing for the creation of richer and more nuanced fragrances.

Each of these advancements underscores the transformative role of supercritical CO₂ extraction in reshaping eco-friendly perfumery, offering both sustainability and creative possibilities.

Conclusion

Supercritical CO₂ extraction is reshaping the way perfumes are made, offering a method that combines eco-conscious practices with exceptional fragrance quality. This approach captures delicate aromatic compounds that traditional techniques might compromise, resulting in scents with greater depth and authenticity.

Beyond its technical strengths, this method brings notable environmental and economic advantages. By eliminating the need for petrochemical solvents like hexane, it ensures no chemical residues are left behind. Since CO₂ naturally converts back into a gas after the extraction process, it can be efficiently recycled within the system, minimizing waste and energy use. This makes it a key player in the clean beauty movement, where transparency and sustainability are highly valued. Economically, the process delivers higher yields and purer extracts, enabling better-quality results with less raw material - boosting both efficiency and cost savings.

As portable systems and refined protocols become more available, adopting this technology is becoming easier. Perfumers can now explore rare and heat-sensitive botanicals, unlocking creative opportunities while staying aligned with sustainable practices.

FAQs

What makes supercritical CO2 extraction a game-changer for perfume production?

Supercritical CO₂ extraction has transformed how perfumes are crafted by offering a gentle yet effective way to extract fragrance oils. Using low temperatures, this process avoids leaving any solvent residues, ensuring the purity of the final product. What’s particularly impressive is how it preserves delicate volatile compounds, allowing the extracts to stay true to the natural scent of the original plant.

Beyond purity, this method captures a wider range of aroma molecules, resulting in fragrances with deeper and more intricate profiles. It’s also a more environmentally conscious approach, blending sustainability with the creation of premium-quality perfumes that honor the essence of natural ingredients.

Why is CO2 extraction considered more eco-friendly than traditional methods?

CO₂ extraction is often seen as a cleaner option because it relies on a closed-loop system. This system recycles the CO₂, cutting down on waste and avoiding the use of harmful organic solvents. As a result, it helps limit pollution and avoids creating hazardous byproducts.

What’s more, the CO₂ used in this process is frequently captured from the atmosphere. This means it doesn’t add to overall greenhouse gas levels, making it a more sustainable choice. Industries like perfume production benefit from this approach, as it aligns with efforts to lower their environmental impact.

Is supercritical CO₂ extraction suitable for all botanicals used in perfumery?

Supercritical CO₂ extraction is a versatile technique, particularly effective for botanicals with sturdy compounds. However, it does have its drawbacks. For materials sensitive to heat, the process can cause changes or even degrade their delicate components. As a result, it’s not the best fit for every raw ingredient in perfumery.

That said, this method stands out for its ability to create pure, high-quality extracts while also being eco-conscious. Its role in advancing sustainable practices in fragrance production has made it an important development in the industry.