3D printing is transforming perfume packaging by offering faster prototypes, reduced waste, and bold design possibilities. This technology allows brands to create detailed, reusable, and eco-conscious designs while cutting costs and production time. For example, L’Oréal reduced prototype development from weeks to just 12 hours using 3D printing. High-end collections like Formula 1 Fragrances and Viktor&Rolf’s Flowerbomb have also used 3D printing to produce limited-edition, high-value packaging.

Key highlights:

- Speed: Prototypes now take hours instead of weeks.

- Cost Efficiency: Eliminates expensive molds and excess materials.

- Design Possibilities: Enables complex shapes and textures.

- Sustainability: Supports refillable systems and reduces waste.

- Personalization: Allows ultra-limited editions for niche markets.

This shift is not just about efficiency but also about redefining how perfume packaging looks and functions, making it more aligned with modern consumer preferences.

Create Premium Retail Packaging | Design for Mass Production 3D Printing

3D Printing for Prototyping and Design Efficiency

3D Printing vs Traditional Manufacturing in Perfume Packaging: Time and Cost Comparison

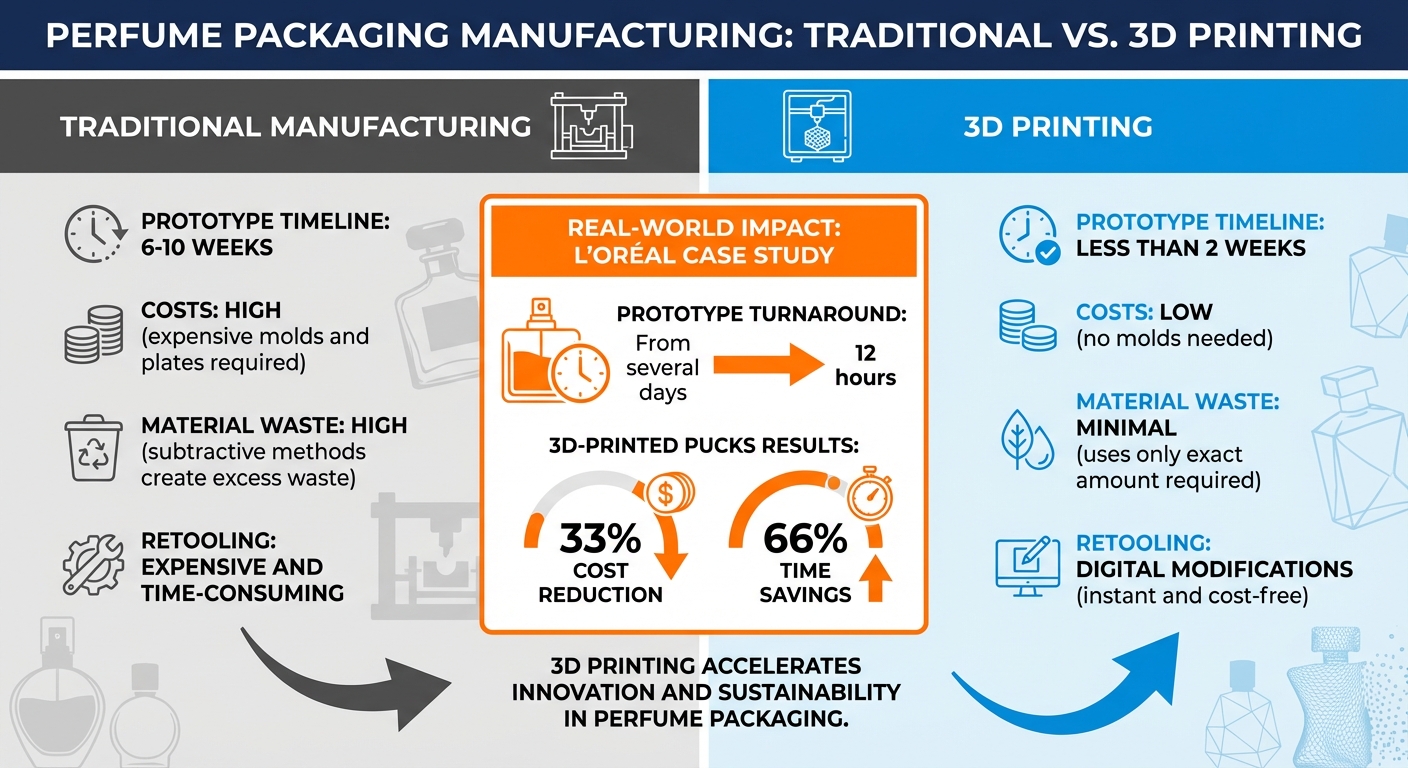

Creating a prototype for a perfume bottle used to be a lengthy ordeal, often taking 6 to 10 weeks when relying on traditional methods like injection molding. With 3D printing, this timeline is drastically reduced to less than 2 weeks. Designers can work directly from digital files, making instant modifications without the need for expensive retooling. This streamlined process not only saves time but also reduces costs significantly.

Cost and Time Savings Compared to Traditional Methods

Traditional manufacturing methods rely on costly molds and plates before a prototype can even be made. On the other hand, 3D printing eliminates retooling expenses and uses only the exact amount of material required, avoiding the excess waste typical of subtractive methods. A great example of this transformation is L’Oréal. By 2020, the company had equipped all its design centers with 3D printers, cutting prototype turnaround times from several days to just 12 hours.

L’Oréal’s collaboration with HP to develop 3D-printed adjustable "pucks" - used to hold perfume bottles during filling - resulted in a 33% reduction in costs and a 66% decrease in production time. This efficiency doesn’t just save money; it also accelerates the design process, allowing for faster iterations and improvements.

Testing and Refining Designs Quickly

3D printing also makes it easier to test and refine prototypes in real-time. Designers can immediately evaluate how a bottle feels in hand, check its weight distribution, and test functional features like cap fit shortly after finalizing a digital design. Nick Sicilian from Anomatic highlights the impact:

"We use it to test the fit, feel, and function of a package, so then adjustments can be made. When a prototype is 3D printed, it provides an excellent approximation of weight distribution".

This rapid testing cycle allows brands to experiment with multiple design variations and catch potential issues early on, avoiding costly revisions down the line. Beyond cost savings, this approach supports creative and eco-conscious design innovations, making 3D printing a game-changer for the industry.

Design Freedom and Customization Options

3D printing has completely transformed the way designers approach their craft, breaking free from the limits imposed by traditional manufacturing. Conventional methods rely on molds that struggle with intricate features like deep undercuts, interwoven structures, or organic shapes. Additive manufacturing, on the other hand, offers a world of possibilities - think hollow exoskeletons, programmable lattices, and sculptural designs that were once impossible to produce. This leap in design capability opens doors to intricate surface textures and customized packaging solutions.

Complex Shapes and Surface Textures

Take technologies like Carbon‘s Digital Light Synthesis (DLS), for example. By building objects layer-by-layer with digital light processing and oxygen-permeable optics, DLS achieves an impressive level of detail. This means brands can now create consolidated parts - highly complex designs that would traditionally require multiple components and assembly steps - produced as a single, seamless piece.

The precision of DLS technology also allows for incredibly fine surface details. Whether it’s thorny branches or floral motifs, these intricate textures require minimal finishing work to look polished. L’Oréal has even remarked that "3D printing is pushing back the bounds of craftsmanship to create high-precision parts of such finesse and complexity that they are difficult for human hands to produce". This kind of design flexibility is especially valuable for creating customized editions tailored to different markets.

Personalized Packaging for Specific Markets

3D printing also makes it feasible for brands to produce ultra-limited editions without breaking the bank, helping them stand out in competitive markets. A great example of this is Designer Parfums and Formula 1, which released aerodynamic-inspired designs in both premium metal and more affordable resin versions. This clever approach allowed them to appeal to both high-end collectors and everyday consumers at the same time.

As Parag Vidyarthi, Managing Director of Designer Parfums, put it: "The process allows us to create stunning shapes and forms that are not achievable using any other process". This adaptability empowers brands to experiment with bold, unconventional designs while still maintaining functionality. It also means they can cater to varying consumer preferences across markets without having to completely overhaul their design processes.

Your Personal Fragrance Expert Awaits

Join an exclusive community of fragrance connoisseurs. Each month, receive expertly curated selections from over 900+ brands, delivered in elegant 8ml crystal vials. Your personal fragrance journey, meticulously crafted.

Try Your First MonthEnvironmental Benefits of 3D Printing in Packaging

3D printing offers a smarter way to produce packaging by using only the materials required. Unlike traditional methods that often involve cutting away excess material or relying on surplus stock for molds, this technology builds objects layer by layer, leaving no room for unnecessary waste.

Reducing Waste Through Precise Manufacturing

Switching from subtractive to additive manufacturing brings clear advantages. Industrial designer Ross Lovegrove highlights this efficiency:

"The use of 3D printing which is extremely efficient, without waste; only the forms needed are produced, much like an F1 car".

Stéphane Beauchemin, Vice President of Sales & Marketing at Plastube, echoes this sentiment:

"Digital printing is also ‘printing on demand,’ so there is less waste".

L’Oréal provides a compelling example of this in action. By incorporating 3D-printed universal pucks - adjustable supports with retractable blades designed to fit various bottle shapes - they achieved a 33% cost reduction and a 66% time savings. This innovation also eliminated the need for multiple bottle-specific parts, showcasing how 3D printing can significantly cut down on materials and time.

Using Biodegradable and Recyclable Materials

Material choice plays a crucial role in sustainable packaging. 3D printing supports advanced options like titanium, stainless steel, and biodegradable plastics that comply with strict regulations. It also enables the creation of mono-material designs - packages made entirely from a single material - making recycling much simpler by removing the need to separate components . This streamlined approach aligns perfectly with refillable design concepts, further enhancing sustainability.

Refillable and Modular Packaging Systems

3D printing is revolutionizing packaging by making refillable and modular designs more accessible. A standout example is the Formula 1 "Engineered Collection", launched in November 2020 by Designer Parfums and Ross Lovegrove. This collection features 3D-printed technopolymer resin exoskeletons inspired by F1 chassis designs. These durable housings hold 75 ml fragrance flasks that users can replace and reuse . This approach not only extends the life of the packaging but also cuts down on single-use waste.

As the global perfume packaging market grows - from $706.8 million in 2023 to a projected $890.5 million by 2032 - such innovations will likely play a key role in shaping a more sustainable future.

What’s Next for 3D Printing in Perfume Packaging

The rapid advancements in 3D printing are opening up new possibilities for perfume packaging, combining cutting-edge design with enhanced functionality. For perfume brands, this means a chance to embrace intricate designs, smarter packaging solutions, and opportunities for businesses of all sizes to innovate. These developments are redefining how materials are used and introducing high-tech features into packaging.

Multi — Material Printing and Advanced Features

Modern 3D printers have the ability to work with multiple materials at once, allowing for packaging components that combine different properties in a single creation. For instance, technologies like Carbon’s Digital Light Synthesis (DLS) use programmable resins that produce parts with both high durability and detailed finishes. These resins can even include heat-activated properties to address issues like brittleness seen in earlier versions.

This means designers can now create complex structures that previously required multiple parts and assembly. For example, integrated lattices or intricate "exoskeletons" can protect delicate glass perfume bottles while delivering bold, eye-catching aesthetics. Ross Lovegrove, the designer behind the Formula 1 Fragrances Engineered Collection, describes the transformative potential of such innovations:

"In the future, we’re going to have to get used to ideas that transform our lives - more organic, more dynamic, and significantly different than what we know today".

These advancements also open the door to integrating electronics directly into packaging, making bottles not just beautiful but interactive and functional as well.

Merging 3D Printing With Smart Packaging

The combination of 3D printing and smart technology is an exciting leap forward. Manufacturers can now design bottles with intricate internal channels to embed conductive inks, creating electrical circuits. They can also pause the printing process to insert components like NFC tags, LEDs, or microcontrollers into the packaging. This hybrid approach enables the creation of smart packaging that can do everything from monitoring fragrance levels to detecting environmental conditions like temperature or humidity. Some designs might even trigger augmented reality experiences when scanned with a smartphone.

NFC (Near Field Communication) technology is already a leader in the interactive packaging space, holding roughly 60% of the market due to its secure and high-capacity data handling. Thanks to 3D printing, these chips can now be seamlessly embedded into perfume bottles without compromising their visual appeal. This means we’re likely to see more packaging that connects directly with consumers, offering both functionality and a personalized experience.

Empowering Small and Niche Brands

One of the most exciting aspects of 3D printing in perfume packaging is its potential to empower smaller brands. Traditional manufacturing involves costly tooling and long production timelines, but 3D printing dramatically reduces both expenses and lead times. This allows for faster prototyping and the ability to produce limited-edition designs on a smaller scale. Parag Vidyarthi, Managing Director at Designer Parfums, highlights this benefit:

"The process allows us to create stunning shapes and forms that are not achievable using any other process".

For niche brands, this technology makes it possible to compete with luxury giants. They can now produce ultra-exclusive editions in quantities as small as 15 to 100 units, adding a sense of rarity to their offerings. A great example is the Formula 1 Fragrances collection, which included technopolymer resin bottles priced between €250 and €333, alongside gold-plated titanium versions that reached €10,000. For smaller players, 3D printing transforms custom packaging from a distant dream into an achievable goal.

Conclusion: How 3D Printing Is Changing Perfume Packaging

3D printing is revolutionizing perfume packaging by making it more sustainable, adaptable, and tailored to individual preferences. Unlike traditional manufacturing methods that involve cutting and molding, which often result in wasted materials, 3D printing uses only the exact amount needed, significantly cutting down on waste. It also speeds up prototyping and reduces costs, boosting production efficiency.

One standout innovation is the creation of refillable packaging systems. For instance, Formula 1 Fragrances has introduced intricate 3D-printed exoskeletons designed to house replaceable fragrance flasks. This allows customers to keep the beautifully designed outer shell while simply replacing the inner bottle. This concept aligns with the growing trend of minimizing waste, similar to Scento‘s preference for smaller decant sizes over full bottles. Such developments reflect a shift toward eco-friendly and customizable packaging solutions.

The creative possibilities with 3D printing are also expanding. This technology enables brands to produce intricate designs and limited editions without the hefty costs of traditional tooling. Even smaller brands can now create exclusive runs of as few as 15 to 50 units.

Additionally, 3D printing caters to the increasing demand for personalized products. The flexibility of the process allows brands to quickly test, refine, and adapt designs to meet consumer preferences. Beyond enhancing packaging aesthetics, these advancements pave the way for a more efficient and sustainable approach to fragrance sampling.

For platforms focused on fragrance discovery, these innovations support a greener approach to sampling and collection building. Precision manufacturing techniques used for refillable luxury bottles can also inspire the creation of reusable atomizers and modular packaging systems, reducing waste while maintaining exceptional quality.

FAQs

How does 3D printing help reduce waste in perfume packaging?

3D printing gives perfume brands the ability to craft precise, on-demand prototypes, making it easier to tweak designs before committing to full-scale production. This process helps save materials and avoids waste by preventing the manufacturing of flawed designs.

With this technology, brands can explore bold and unconventional shapes while staying mindful of sustainability. It’s a win-win: reducing packaging waste and promoting environmentally conscious practices within the fragrance industry.

How does 3D printing benefit small and niche perfume brands?

3D printing opens up exciting possibilities for small and niche perfume brands to craft intricate, custom packaging that truly stands out. Unlike traditional molding methods, this technology enables the creation of unique shapes, textures, and finishes, allowing brands to weave a visual narrative that resonates with collectors and enthusiasts. Plus, it eliminates the high costs associated with steel molds, making it a practical choice for limited-edition or one-of-a-kind packaging.

For newer brands, 3D printing simplifies the prototyping process, offering a quicker and more efficient way to perfect bottle designs before committing to full-scale production. This approach not only saves time but also reduces financial risks, especially when experimenting with new fragrances. The precision of 3D printing ensures high-quality components - like caps and sprays - while its on-demand production model helps cut down on waste, aligning with eco-conscious values. These benefits make 3D printing a smart choice for brands looking to create exclusive, high-quality packaging that reflects their unique vision.

How is 3D printing transforming personalized and exclusive perfume packaging?

3D printing has opened up exciting possibilities for perfume brands, enabling them to craft intricate, custom designs that would be challenging - or prohibitively expensive - to achieve using traditional methods like glass-blowing or injection molding. By constructing objects layer by layer from a digital blueprint, brands can experiment with unique shapes, textures, and fine details without relying on large-scale production tools. This method also makes it easier to produce personalized or limited-edition packaging on demand.

Luxury brands have already embraced this technology in striking ways. For instance, Viktor & Rolf celebrated Flowerbomb’s 15th anniversary with rose-gold “thorn-and-flower” bottles, each meticulously handcrafted and priced at $2,500. Similarly, Formula 1 introduced gold-plated titanium exoskeleton perfume bottles, blending cutting-edge design with exclusivity. On a smaller scale, niche retailers like Scento use 3D printing to create uniquely styled atomizers for limited-edition collections. This approach not only allows for standout designs but also helps minimize waste by avoiding the pitfalls of mass production.