The fragrance industry is shifting towards carbon-neutral production to reduce its environmental impact. This involves replacing traditional ethanol, often sourced from crops, with ethanol made from captured industrial emissions. For example, Coty Inc. launched Gucci’s "Where My Heart Beats" in 2023, using 100% carbon-captured ethanol, a move that decreases water use and agricultural dependency.

Key points:

- Ethanol’s role: Makes up 80% of most perfumes, traditionally derived from crops like sugarcane, which require significant land and water.

- Carbon-captured ethanol: Uses industrial waste gases, saving water and reducing emissions.

- Challenges: High costs, technical hurdles, and reliance on fossil-fuel-derived carbon.

- Future innovations: Biotechnology and upcycling are creating sustainable fragrance ingredients, such as lab-grown sandalwood and recycled citrus peels.

The industry is also addressing emissions across production, packaging, and transportation while using offsets and renewable energy to meet carbon-neutral goals. However, scaling these practices remains complex, with costs and supply chain limitations being major barriers.

The Truth About How Your Perfume Is Made | Rewinding Perfume

What Carbon — Neutral Perfume Production Means

Five — Step Process for Achieving Carbon Neutrality in Perfume Production

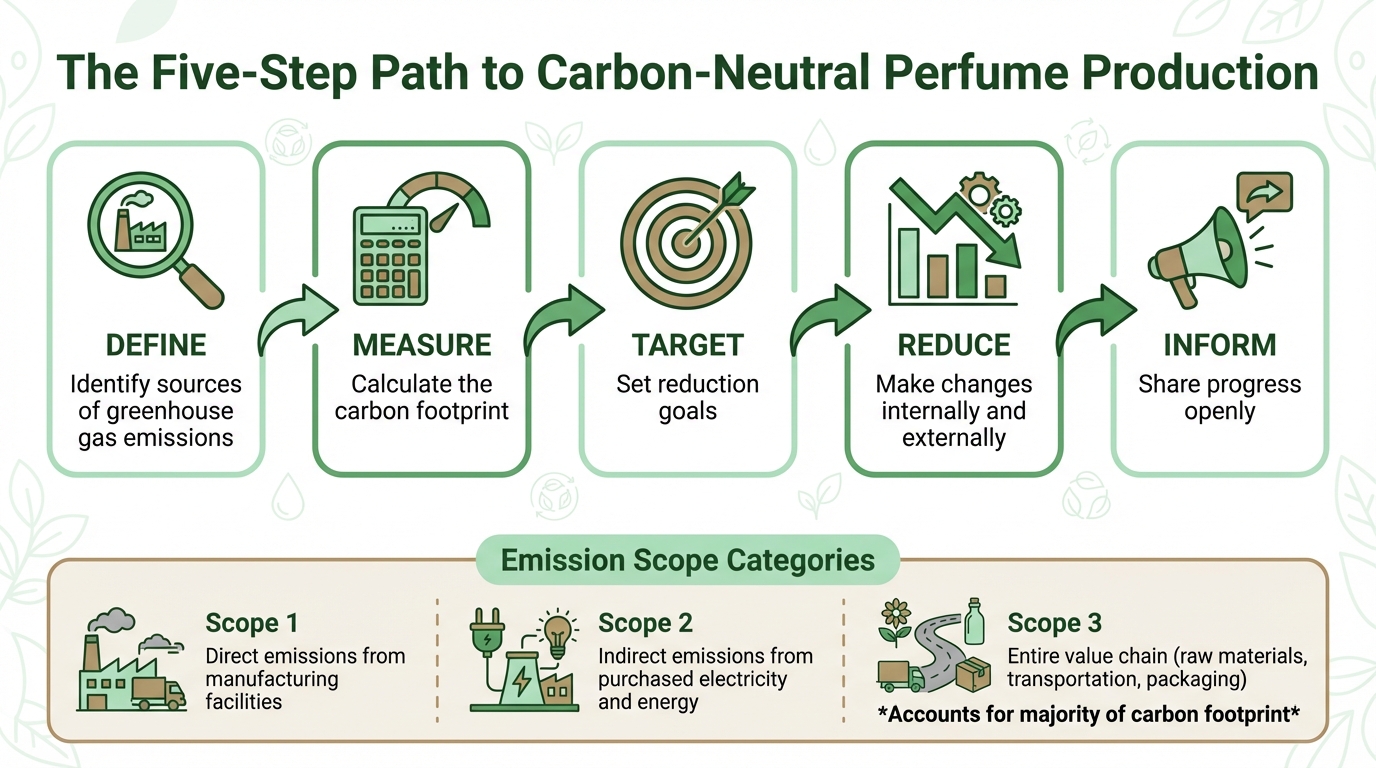

Carbon neutrality in perfume production involves balancing the emissions generated throughout a product’s lifecycle by reducing them where possible and offsetting the rest. To achieve this, the fragrance industry typically follows a structured five-step process: Define (identify sources of greenhouse gas emissions), Measure (calculate the carbon footprint), Target (set reduction goals), Reduce (make changes internally and externally), and Inform (share progress openly).

This strategy focuses on three main areas of emissions. Scope 1 includes emissions directly from manufacturing facilities. Scope 2 addresses indirect emissions from purchased electricity and energy. Scope 3, which often accounts for the majority of a perfume’s carbon footprint, covers the entire value chain - raw materials, transportation, packaging, and more. These categories help guide the industry in implementing practical reduction and offset solutions, which are explored further in this article.

Lifecycle Emissions in Perfume Production

When it comes to carbon neutrality, understanding the lifecycle emissions of a perfume is essential. From sourcing raw materials to manufacturing, every step contributes to the overall footprint. Ethanol, which makes up about 80% of most fragrances, is the largest contributor to these emissions. Traditionally, ethanol is derived from crops like sugarcane or sugar beets, which require significant agricultural land and water. These practices have also been linked to deforestation in regions such as Brazil’s Atlantic Forest.

In early 2022, Coty achieved a major breakthrough at its Granollers, Spain, facility by incorporating over 20 metric tons of carbon-captured ethanol from LanzaTech into its manufacturing process. This ethanol is produced from recycled industrial emissions rather than conventional agricultural methods. Dr. Jennifer Holmgren, CEO of LanzaTech, highlighted the significance of this innovation:

"After two years of working side by side with Coty scientists to develop a high-purity ethanol suitable for use in fine fragrances, we are excited to see Coty bring the first globally distributed fragrances made from CarbonSmart™ ethanol to market".

This carbon-captured ethanol production requires minimal water and reduces agricultural dependence. LanzaTech’s technology has the potential to replace up to 30% of crude oil usage and cut global CO₂ emissions by 10%.

The Role of Offsets and Renewable Practices

In addition to internal improvements, external measures play a crucial role in achieving carbon neutrality. The process involves two key strategies: internal abatement, which focuses on reducing emissions within the supply chain, and external compensation, achieved through carbon offsets. Internal abatement includes steps like transitioning to renewable energy sources, often verified using Energy Attribute Certificates (EACs), to lower Scope 2 emissions.

Carbon offsets, on the other hand, support projects that reduce or remove greenhouse gases, such as reforestation or renewable energy initiatives. These projects generate credits that can balance out residual emissions. However, recognizing that offsets alone are not a complete solution, the industry is increasingly adopting insetting - directly addressing emissions within the value chain.

Sue Nabi, CEO of Coty, explained the dual benefits of these efforts:

"The shift to carbon-captured ethanol is not only the right thing to do, but it makes commercial sense too - with today’s consumer rightly demanding that their favorite brands share their commitment to sustainability".

Coty has committed to reducing its absolute CO₂ emissions by 30% by 2030, reflecting the industry’s dedication to measurable and long-term environmental goals.

Methods for Creating Sustainable Perfume Ingredients

The fragrance industry is adopting cutting-edge methods to minimize its environmental footprint. Advances in biotechnology and refined natural extraction techniques are leading the way, offering more sustainable ways to produce perfume ingredients.

Biotechnology in Fragrance Ingredient Development

Biotechnology is revolutionizing how scent molecules are created. Through metabolic engineering, scientists transform microorganisms like Escherichia coli and Saccharomyces cerevisiae into "cell factories" that produce key fragrance compounds such as patchoulol, santalol, and limonene via fermentation.

One standout innovation is gas fermentation, which repurposes industrial waste gases from steel production into pure ethanol. LanzaTech has already produced over 20 million gallons of this ethanol, preventing the release of 115,000 tons of CO₂ into the atmosphere. Remarkably, this process uses minimal water and land resources.

In May 2021, BASF and LanzaTech achieved a breakthrough by producing n-octanol at a laboratory scale. Using gas fermentation, they converted industrial waste gases like carbon monoxide and hydrogen into fatty alcohols, which can replace palm oil or petroleum-derived ingredients in cosmetics and fragrances. Freya Burton, Chief Sustainability Officer at LanzaTech, envisions a future where raw materials like ethanol are derived entirely from waste carbon:

"We see a future where agricultural cultivation is reserved for food wherever possible. Other raw materials such as ethanol... are made directly from waste carbon".

Another example is Symrise’s "Dreamwood", a sustainable sandalwood molecule created through fermentation. Unlike traditional sandalwood, which requires over 25 years for trees to mature, this biotech solution delivers consistent quality while bypassing the environmental challenges of tree harvesting. Additionally, biotechnology enables the production of enantiomerically specific compounds, ensuring precision and consistency that natural harvests often lack due to seasonal or climatic variations.

While biotechnology is reshaping ingredient synthesis, traditional methods are also evolving to become more resource-efficient.

Natural Extraction Methods

In tandem with biotechnological advances, improved extraction techniques are helping to reduce environmental impact. Methods like supercritical CO₂ extraction are gaining traction for their ability to recycle solvents and minimize chemical waste. This approach not only requires less energy than traditional steam distillation but also produces purer aromatic compounds.

The concept of upcycling is another game-changer. Givaudan’s "Citrus Circularity" program transforms leftover orange, lemon, and grapefruit peels from juice production into essential oils. This initiative reduces the need for dedicated fragrance crops by turning food industry waste into valuable raw materials. By closing the loop on resource use, upcycling aligns with the industry’s sustainability goals.

| Feature | Traditional Plant Extraction | Chemical Synthesis | Biotechnology (Microbial) |

|---|---|---|---|

| Source | Crops (e.g., sugarcane, flowers) | Petroleum/fossil fuels | Waste carbon, biomass, or sugar |

| Carbon Impact | High (deforestation, transport) | High (fossil fuel dependence) | Low to negative |

| Consistency | Variable (seasonal/climatic) | High | High |

| Scalability | Limited by land availability | High but resource-intensive | Growing |

These advancements are steering the fragrance industry toward carbon-neutral production. By shifting from resource-intensive extraction methods to processes that actively reduce waste and emissions, perfume makers are redefining sustainability in the world of scent.

Technology and Partnerships for Carbon Neutrality

The fragrance industry is leaning on advanced technologies and collaborations to fast-track its journey toward carbon-neutral production. These efforts are reshaping how ingredients are sourced, environmental impacts are measured, and sustainable practices are scaled.

AI Tools for Reducing Carbon Footprints

Cutting-edge digital tools are helping brands precisely measure and lower their carbon emissions. For instance, eco-design systems now allow brands to calculate the environmental impact of their formulations. One standout feature is the use of "ingredients checkers", which evaluate the sustainability of components before they make it into the final product.

This is especially impactful given that ethanol makes up as much as 95% of a fragrance’s composition. By employing technology to monitor and refine the use of this key ingredient, brands can make significant strides in reducing their carbon footprint. Additionally, these tools support supply chain segregation, enabling companies to move beyond "mass balance" methods - which combine traditional and sustainable alcohol - to formulations made entirely with recycled carbon.

These innovations are laying the groundwork for broader collaborations that are crucial for achieving carbon neutrality across the industry.

Partnerships Powering Sustainability

While digital tools play a vital role, strategic partnerships are equally essential in driving sustainable change in fragrance production. A notable example is the Coty — LanzaTech collaboration, which led to the launch of Gucci’s "Where My Heart Beats" Eau de Parfum in April 2023. This fragrance stands out as the first globally distributed perfume made with 100% carbon-captured alcohol. Highlighting the importance of this partnership, Coty CEO Sue Y. Nabi stated:

"Sustainability is the ultimate driver of innovation and Coty is focused on creating outstanding products that are truly clean and green. Ethanol is the number one ingredient purchased for the fragrance category and over time this partnership with LanzaTech will significantly reduce the environmental impact of our products."

In another milestone, three LVMH brands - Parfums Christian Dior, Givenchy Parfums, and Kenzo - teamed up with the cooperative CristalCo to support the agro-ecological transformation of 380 hectares of beetroot farmland in France. This initiative uses regenerative agriculture to produce low-carbon alcohol, which now fulfills about 45% of their alcohol requirements. Additionally, in early 2025, Intact Regenerative began operations near Orléans, France, utilizing patented technology to process leguminous plants. This method cuts production emissions by over 80% and requires 75% less water compared to traditional approaches.

These examples showcase how technology and collaboration are reshaping the fragrance industry, setting a new standard for sustainability.

sbb-itb-fb213bc

Benefits of Carbon — Neutral Perfume Production

Environmental Impact Metrics

Switching to carbon-neutral perfume production brings measurable environmental advantages. One standout innovation is carbon-capture technology, which intercepts industrial waste gases - like those from steel mills - and transforms them into high-purity ethanol. This process not only prevents greenhouse gases from being released into the atmosphere but also provides a sustainable alternative to traditional ethanol. Given that alcohol accounts for roughly 80% of how luxury perfume is made, this shift substantially lowers the industry’s carbon footprint.

Another key benefit is water conservation. Studies show that producing alcohol from captured carbon requires far less water compared to conventional agricultural methods. By minimizing the reliance on large-scale farmland, these practices also help safeguard natural habitats and support biodiversity. Together, these advancements highlight how the fragrance industry is making tangible progress in reducing its environmental impact.

With the fragrance and flavor market projected to generate 800,000 metric tons of material by 2025, the potential for these sustainable methods to drive meaningful change is enormous. Beyond cutting emissions, the industry is also embracing upcycling to enhance resource efficiency.

Upcycling and Resource Efficiency

Upcycling plays a pivotal role in creating a circular production model by transforming waste into valuable fragrance ingredients. As Dr. Shimei Fan, Chief Scientific & Sustainability Officer at Coty, eloquently put it:

"This is the ultimate upcycling... converting industrial emissions, which would have otherwise been released into the atmosphere, into alcohol for our fragrances".

This approach not only reduces waste but also underscores how innovative solutions can redefine sustainability in the perfume industry.

Challenges and Research Gaps in Carbon — Neutral Perfume Production

Scaling Biotech and Sustainable Practices

Producing carbon-neutral perfumes at scale is no small feat. One major hurdle lies in the cost and complexity of converting industrial CO₂ into ethanol. As Martin Mulvihill, Co-founder and Managing Partner at Safer Made, explains:

"Because CO₂ only has one carbon, combining CO₂’s single carbon atom into a multi-carbon alcohol is energy intensive."

The fragmented nature of the fragrance industry further complicates efforts to implement sustainable supply chains. With numerous small and medium-sized businesses operating independently, aligning practices across the sector is an uphill battle. While large corporations can afford cutting-edge biotechnology and AI-driven formulations, smaller fragrance houses often lack the financial resources to adopt these expensive solutions. Adding to this, climate extremes disrupt the availability of natural raw materials, placing additional strain on already fragile supply chains.

Even natural alternatives come with their own set of challenges. Take sustainably managed sandalwood, for example. These trees require at least 20 years to mature before their fragrant heartwood can be harvested. This long timeline demands patience and significant financial stability - qualities that many producers find hard to sustain.

These operational obstacles naturally lead to broader financial and research challenges.

Balancing Costs and Long — Term Benefits

The financial demands of scaling sustainable practices add another layer of complexity for the fragrance industry. On average, fragrance companies allocate about 8% of their revenues to research and development. Transitioning to sustainable methods, however, requires significant upfront investments in new technologies and infrastructure. For instance, premium fragrances that incorporate carbon-captured alcohol often come with high price tags, reflecting the substantial costs involved.

Another pressing challenge lies in understanding and addressing Scope 3 emissions, which account for roughly 95% of a natural fragrance ingredient’s carbon footprint. Bernard Toulemonde, a consultant and natural ingredients expert, highlights this gap:

"It’s then easy to understand the breadth of the gap between the data published until now, limited to Scopes 1 and 2, versus the reality of the actual footprint encompassing the full value chain."

Data accessibility further compounds the problem. Fragrance formulas are tightly guarded secrets, making it nearly impossible to gather the comprehensive information needed for accurate Life Cycle Assessments. Without standardized methods and transparent data sharing, creating effective carbon-reduction strategies remains a daunting task.

Tackling these financial and data-related challenges is essential for unlocking the full potential of carbon-neutral production. Addressing these barriers will not only help the industry meet its sustainability goals but also ensure its long-term commercial viability.

Conclusion

The rise of carbon-neutral production is reshaping the perfume industry, redefining how fragrances are crafted, marketed, and perceived. By replacing petrochemicals and traditional agricultural ethanol with carbon-captured alcohol and biotech-derived materials, the industry is turning industrial waste into high-end products - an impressive form of upcycling.

This shift isn’t just about environmental responsibility; it’s also delivering measurable business benefits. Reports show that adopting sustainable practices can cut costs while driving growth. Millennials and Gen Z consumers, who value transparency and accountability, are pushing brands to embrace these changes. The Gucci fragrance priced at €330 for 100ml illustrates that luxury and sustainability can coexist, proving that environmental advancements don’t have to compromise premium pricing.

For the industry to fully embrace this transformation, leaders need to integrate sustainability into their research and development efforts. Aligning with the United Nations Sustainable Development Goals, utilizing tools like the EcoScent Compass, and investing in refillable packaging are critical steps. Consumers also play a role by supporting brands committed to transparency and lifecycle assessments, sending a clear signal to the market.

Ultimately, carbon-neutral perfume production is more than a trend - it’s a forward-thinking approach that converts industrial emissions into premium fragrance ingredients. This isn’t just progress; it’s a glimpse into the future of the fragrance world.

FAQs

How does using carbon-captured ethanol make perfume production more sustainable?

Carbon-captured ethanol offers a forward-thinking alternative to traditional corn-based ethanol. This process transforms industrial CO₂ into alcohol, drastically cutting down its environmental footprint. Unlike its corn-derived counterpart, it uses almost no water, doesn’t rely on farmland, and eliminates the need for fertilizers and herbicides.

By slashing carbon emissions tied to perfume production, this method addresses climate change while also helping to preserve biodiversity. It represents a crucial move toward achieving carbon-neutral fragrance creation.

What challenges do brands face in creating carbon-neutral perfumes?

Producing perfumes that are carbon-neutral is no easy feat, and the challenges begin right at the source. Finding sustainable ingredients is a major obstacle, especially since beloved fragrance staples like sandalwood and rose oil depend on plants that grow slowly or are often overharvested. Addressing this issue means committing to responsible replanting, building ethical supply chains, and working closely with local communities - steps that not only add complexity but also drive up costs.

The production process itself poses additional hurdles. Traditional methods for extracting essential oils consume vast amounts of energy and water, leaving behind considerable waste. Shifting to low-carbon alternatives, such as bio-based solvents or ethanol derived from captured carbon, demands significant investment in new infrastructure. On top of that, these alternatives must undergo extensive testing to ensure they don’t compromise the quality of the final scent.

Another layer of difficulty comes with adopting science-based emissions tracking and incorporating greener technologies. These efforts often require hefty upfront spending, which can be particularly burdensome for smaller brands. Striking a balance between these necessary investments and keeping products affordable for consumers is a critical challenge in making carbon-neutral perfumes a reality.

How do biotechnology and upcycling make fragrance ingredients more sustainable?

Biotechnology and upcycling are reshaping how fragrances are made, aiming to lessen their impact on the planet. Through biotechnology, cutting-edge methods are being developed to replace fossil-based carbon in fragrance ingredients. One example is the use of microbial technology to convert industrial emissions, like carbon-rich waste gases, into renewable ethanol and essential aroma molecules. This process not only reduces the reliance on fossil fuels but also significantly cuts the carbon footprint of perfume production.

Upcycling, on the other hand, focuses on giving new life to materials that might otherwise be discarded. By transforming byproducts or secondary materials into new fragrance ingredients, this approach helps conserve resources and minimizes waste. Together, these innovations are paving the way for a more sustainable fragrance industry by reducing greenhouse gas emissions, decreasing dependence on petrochemicals, and supporting a circular economy. However, challenges such as scaling these solutions and managing costs still need to be addressed as the industry moves closer to carbon-neutral production.